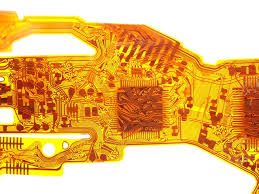

Flexible Circuit Board Be Made

A flexible printed circuit board is a printed circuit board that has the ability to flex without damage or deformation. This makes it easier to install and provides more flexibility than a rigid circuit board, which is important for some applications. It’s also more durable and resistant to heat than rigid boards, making it suitable for a wide range of environments and conditions.

A flex PCB can be made from a variety of materials, including polyimide. This is a common choice as it’s tough, very flexible, and able to withstand constant movements and vibrations. It can even be used in high-temperature applications. Other materials include FR4, polyamide, and aluminum-based laminates. Depending on the application, a flex circuit board may also need stiffeners or other structural materials.

Creating a flexible circuit board requires careful planning and design. The bending radius and the amount of stress that will be placed on the copper must be considered in the early stages of the design. This will help to prevent damage during bending, and it will make the finished product more reliable. The bending radius is the minimum angle at which the board can be bent before it is damaged, and it should be calculated based on the number of layers in the PCB. Conductors should be staggered in multi-layered flex circuits to reduce the strain on the copper. It’s also important to avoid 90-degree bends as this will cause a high level of stress.

How Thin Can a Flexible Circuit Board Be Made?

The thickness of the substrate is another factor to consider. A thinner substrate will offer more bending capability. It will also allow for less plated copper to be used. This will result in a smaller interconnect footprint and smaller spaces between lines. This can be beneficial for small devices that require a minimal space to operate.

Another important consideration is the thickness of the dielectric layer. A thinner dielectric layer will increase a flex PCB’s bending capabilities. Thicker layers can be difficult to etch, which can interfere with the integrity of the copper traces and the solder joints.

Finally, the type of metals used in a flex circuit board should be considered. Metal domes are the most common, but they can be replaced by other types of metal. For example, stainless steel or aluminum are popular choices for flex PCBs. Choosing the right metals can ensure that the components and conductors are protected from harsh environments.

Ultimately, the most important consideration for a flex circuit board is the quality of the workmanship and fabrication. It is crucial to choose a reputable CM that has experience working with flex circuits. They can provide advice on design, manufacturing, and assembly. They can also provide a detailed QA report to guarantee that the product meets all requirements. They should follow IPC-610 standards, which gives recommendations for the acceptability of a flex circuit board.